Hi iMaterialise fans,

Oskar’s Continuously Variable Transmission (CVT) is based on one-way bearings. Many CVTs are based on friction. A well-know example is the DAF Variomatic (https://en.wikipedia.org/wiki/Variomatic), which uses a push belt between conical pulley plates. This is also used for bicycles by Peyman (https://www.peymancvt.co.uk/). Another friction-type of CVT is the Enciolo CVP (Continuously Variable Planetary, https://enviolo.com/technology/), which uses a planetary system of swivelling steel balls. Recently, Ratiorez announced their RatioZero CVT (https://www.ratiozero.com/, https://www.youtube.com/watch?v=mWJHI7UHuys) that uses one-way bearings (cf ratchets) instead of friction. The use of one-way bearings has the main benefit of being much less tolerances critical than friction-based CVTs. This brings the CVT concept into the realm of makers with 3D-printer.

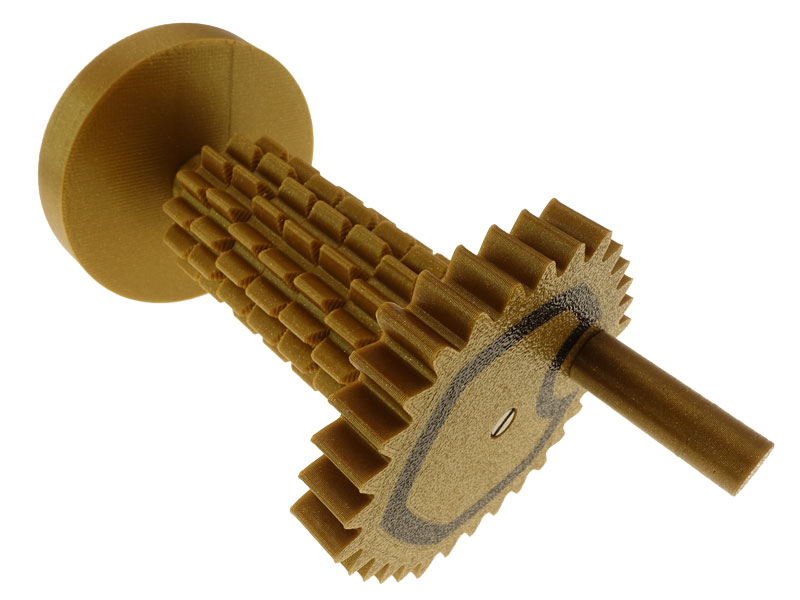

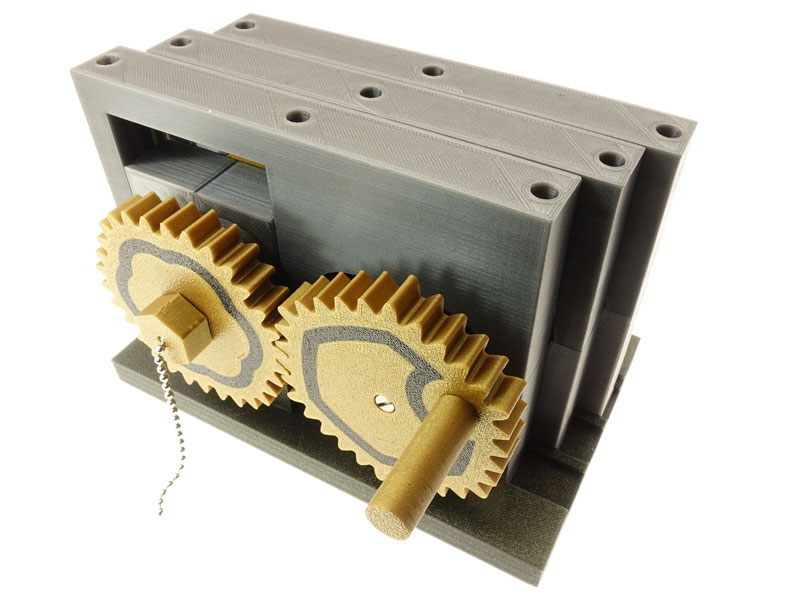

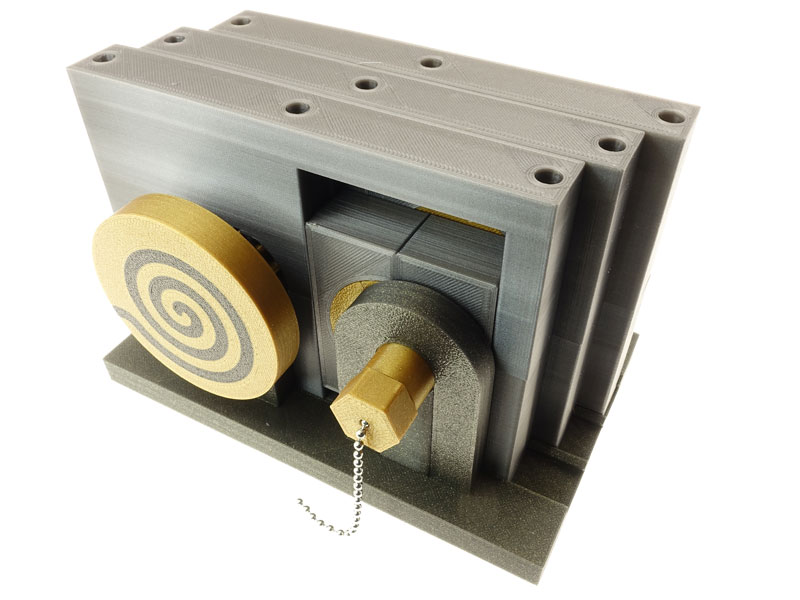

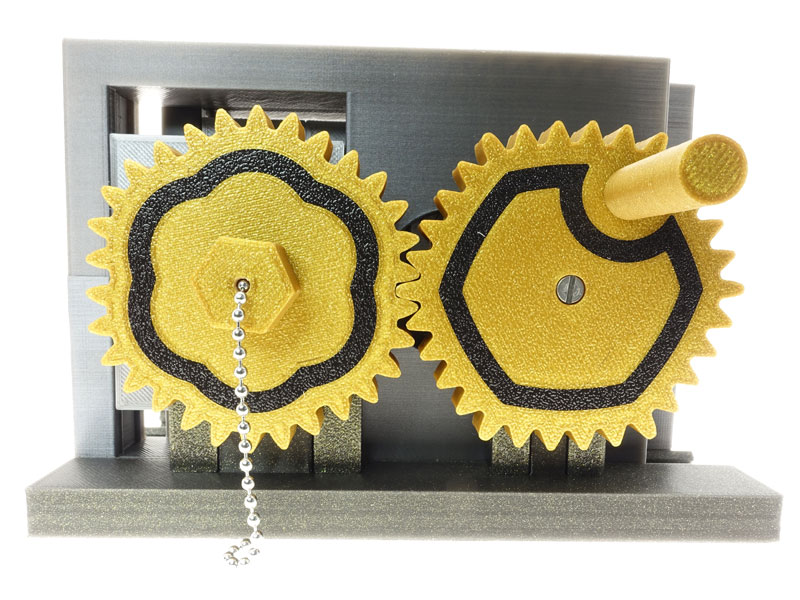

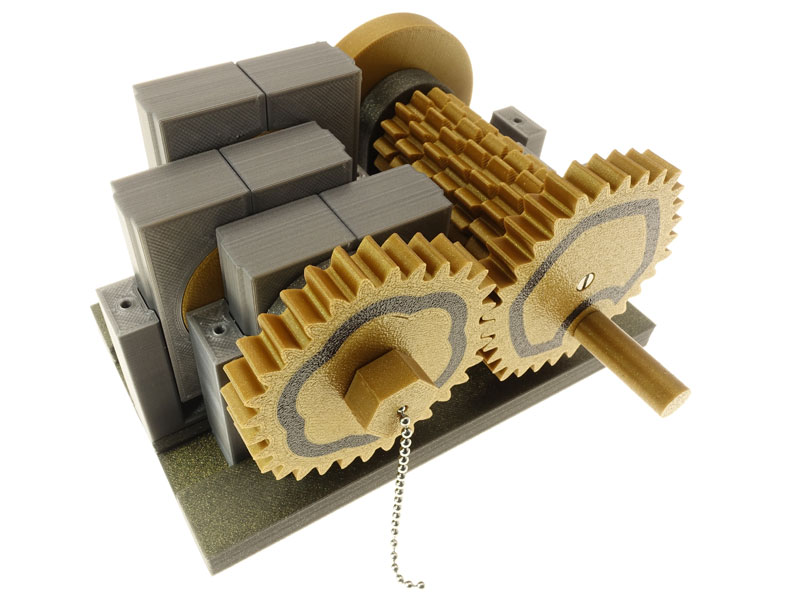

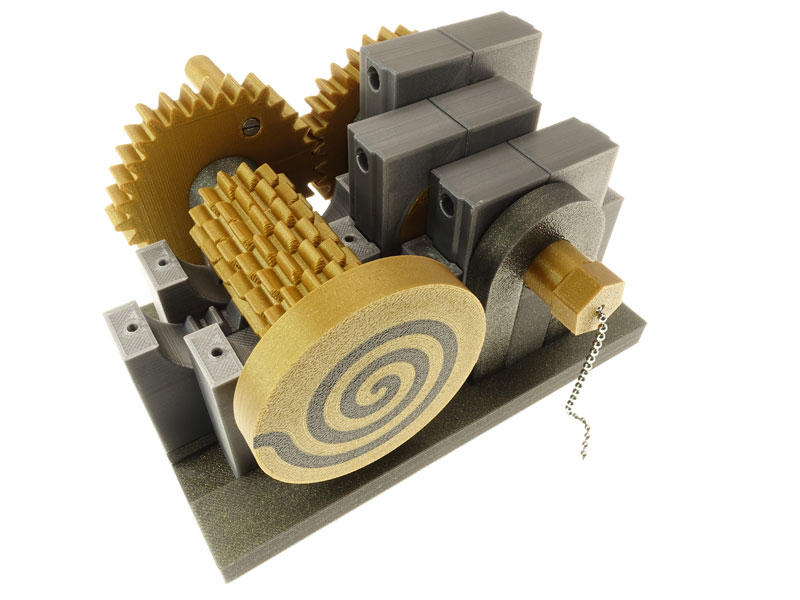

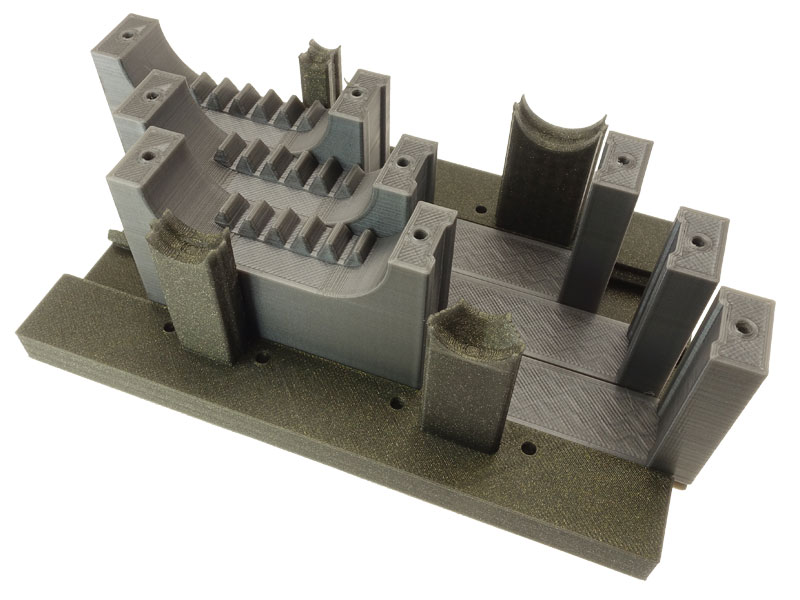

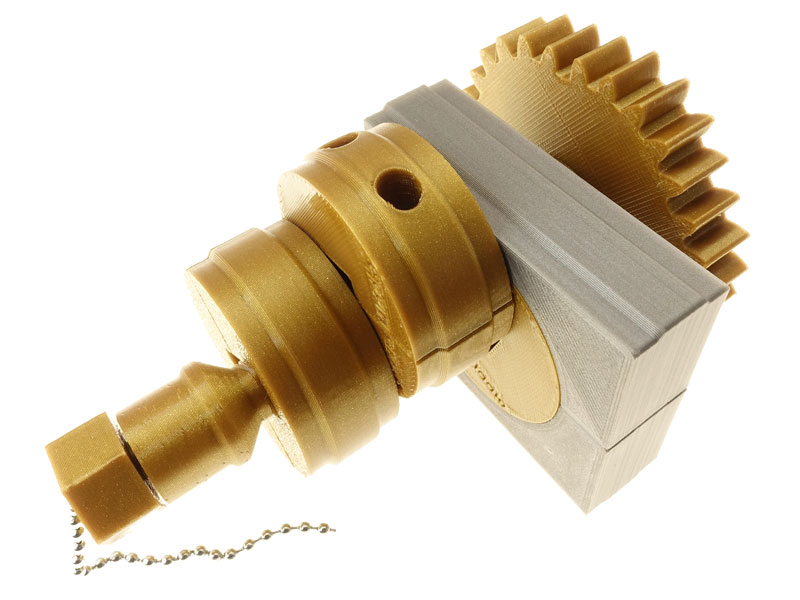

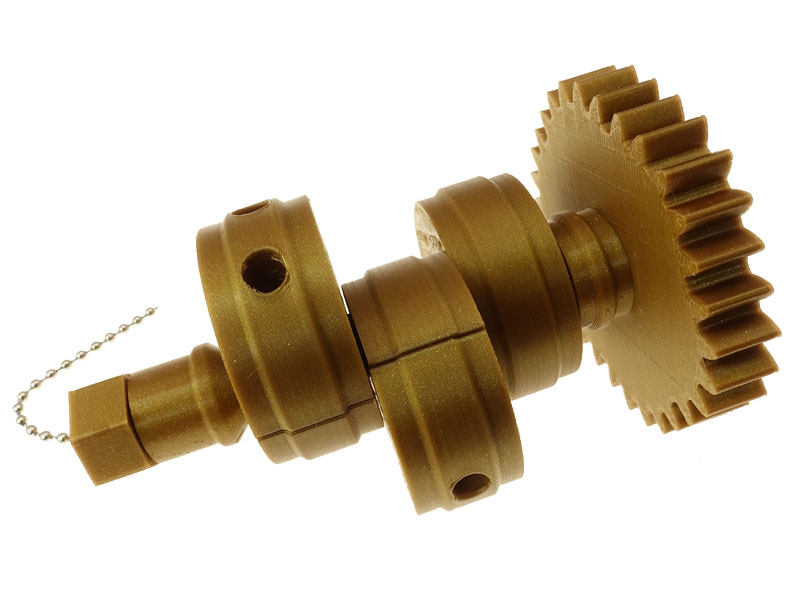

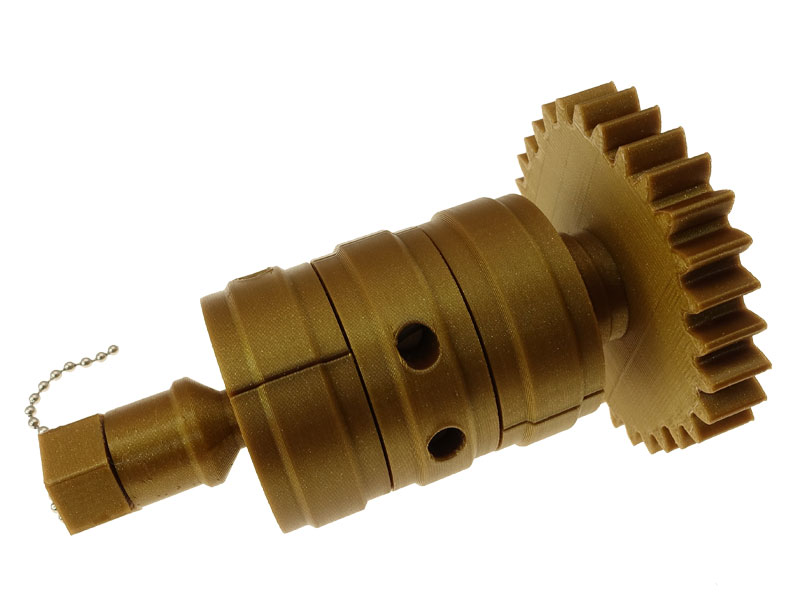

My CVT uses a piston-like system. A ball chain is just to adjust stroke distance. There are three pistons, with relative phases of 0, 120 and 240 degrees, similar to three-phase electricity. Each piston drives two gears, connected with one-way bearings to the output shaft. One gear is for the forward motion of the piston, and one for the backward motion. So there is a total of six gears, and the system has six phases, one for each gear. The drive shaft is driven with a hexagonal gears. The purpose of the hexagonal gears is to even out the motion of the pistons. This assures that a piston is sliding at a constant speed when it is driving the output axles. This compensation system works exactly for any gearing ratio between the manually-driven input and the output shaft.

Watch the YouTube video.

Download the CAD file to print-it-yourself.

Buy the puzzle at my iMaterialise Shop.

Read more at the Non-Twisty Puzzles Forum.

Check out the photos below.

Enjoy!

Oskar

Uploading: Oskar’s-CVT—view-14.jpg… Uploading: Oskar’s-CVT—view-15.jpg…

Uploading: Oskar’s-CVT—view-14.jpg… Uploading: Oskar’s-CVT—view-15.jpg…