Hi there,

I have developed a new laser projection jewelry technology called (Mem-Gems) that I think could be a perfect complement to i.materialise 3D printing and metal casting capabilities. Many of my early customers have asked for their Mem-Gems to be embedded in rings and pendants, and I have referred them to their local jewelers. However, I think that if I could have some design guidelines for them I am sure there would be a lot of interest, either in making them a ring with embedded Mem-Gem or guidelines for them to do it themselves.

I am planning to make my own wedding band with an embedded Mem-Gem as a proof of concept, so I will document my learnings along the way. So far, I have found that you are out of stock of white gold

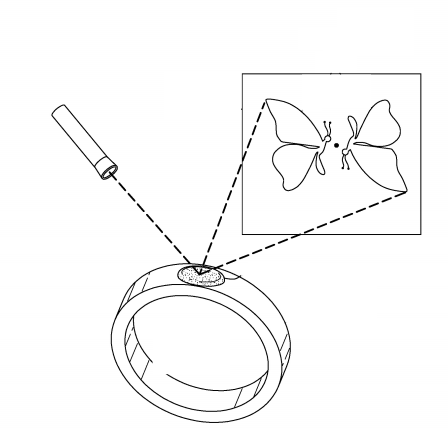

I will try regular 14k white gold. I want to embed the Mem-Gem with a “Gypsy” aka “flush” bezel set, which means some precision engineering on the embossed feature. I am planning to make my ring look like this:

I have a degree in Mechanical Engineering, and am familiar with Solidworks and Autodesk Fusion 360 so I think I could probably pick up the software pretty quick. Any suggestions on which 3D software to use for the 3D design of a custom wedding ring that can house a Mem-Gem? Any other tips are much appreciated!