Hi,

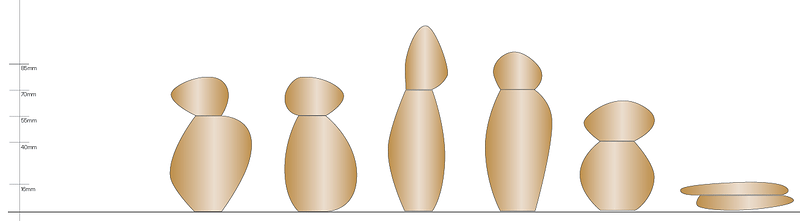

I have a cosmetic packaging project with 5 pieces around 70 x 20 x 20mm or under, 5 pieces about 20 x 30 x 40mm or under, and 2 pieces that are about 50 x 50 x 16mm. All are shells with a 16-20mm hole for an opening.

I’d like this to be cast in bronze, natural PU coating.

- I know that the lead time is 15 business days for bronze, does that change with more pieces?

- How thin can I make my shell considering my shapes?

- Will all of these pieces be cast together, or will my file be split in two?

- Is there any way to expedite my order?

This is my first time ordering, so I want to get it right!

Thank you,

Carson