Hi everyone,

I have already printed some things here at Materialise and I am enthusiastic. At home I also use an FDM printer. But now I would like to make jewelry or key chain, etc.

With these materials:

Steel

High-Detail Stainless Steel

Silver

Brass

Bronze

Aluminium

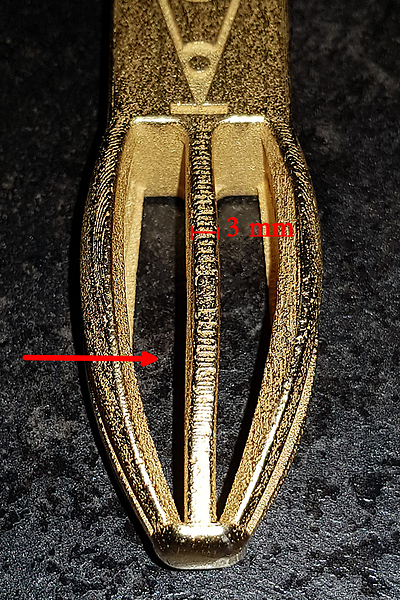

Fine details should of course be beautifully presented. From my FDM printer, I know that vertical details are usually displayed nicely, but how about these metals and Silver with the different printing techniques, should I upload the part horizontal or vertical position? For the strength, it will no matter, right?

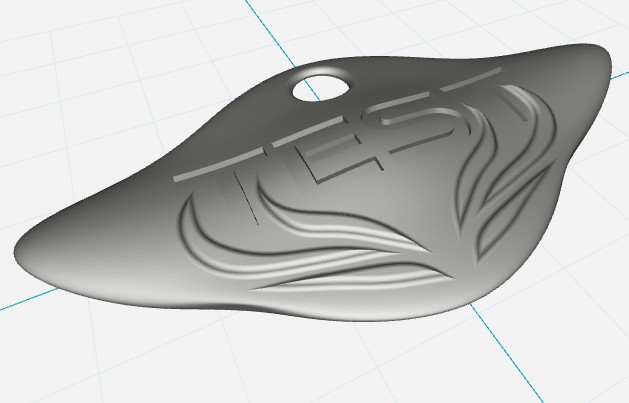

I have attached an image sample (curved Surface and also Details on back side)

Thank you for the Information

Klaus