Spotlight on Lou Keppler

Lou Keppler is a significant part of the team at Materialise, our parent company. As Product Development Principal, he has his hands in many projects and plays several roles in the evolution of the 3D printing process.

Keppler has always had a love for technology, and coupled with his surgeon father’s influence, he has a job at Materialise that seems custom made for him.

Lou Keppler graduated with a BA from Case Western and has been a part of the Materialise team for almost 8 years. He was at the headquarters in Belgium for 6 years before returning to the United States with his wife upon the birth of their daughter.

Keppler’s day to day roles mostly focus on orthopedic technology, creating 3D printing devices that aid surgeons in many different areas. His experiences often take him to cadaver labs to measure and photograph human bodies to make the printing accurate for the surgeon’s to operate.

When asked what his favorite project has been to date, he sites shoulder guides that have been recently been cleared by the FDA, and they will be showcased at a San Diego Shoulder Conference, the AAOS. He also has worked on a putting green for Don Jon Orthopedics, more commonly known as DJO. Keppler says there are many other favorites, but because they are in the design phase, he cannot disclose them.

Keppler also has put his 3D printing skills to practical use as well. Upon first moving to Belgium, he discovered the showerhead in the bathroom was broken. Not an item easily found, he printed it and was able to make the new showerhead without the hassle of shopping or ordering it.

When asked about his involvement in the local Maker community Lou spoke about organizing a Hardware Startup Meetup in Pittsbugh:

“I help organize a Hardware Startup Meetup in Pittsburgh. This has been in collaboration with TechShop and AlphaLab Gear, both of which are huge supporters for making physical objects- not just software startups. At these meetings we see a wide range of makers spanning from artists to robotics engineers all of which have come together to learn from each other and see what we can make.

While the TechShop has some MakerBot 3D printers on site, they are pretty low resolution and have limited materials to work with. This may work great for a first iteration or to sketch out ideas, but once a piece comes to a more refined stage something better is needed. This is where I’ll point them to i.materialise. The artists especially like the metals and ceramic finishes which have been used for jewelry or decorative housewares. The robotics crew likes the higher resolution parts since they need the high tolerances to make their machines run smoothly. “

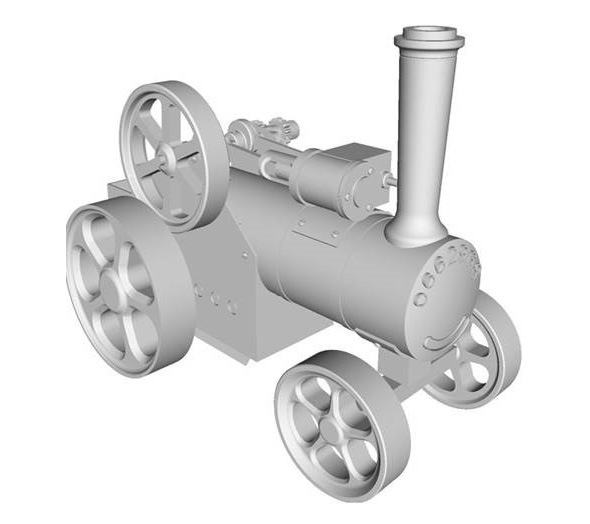

Personally, I tend to use 3D printing for fun at home. For example, I have a 2 year old daughter who likes to play with a toy train set so adding new cars, engines, or scenery is a blast. It also helps since these toys seem to always be disappearing between her and the dog. I must admit that I use others’ designs for these trains, from thingyverse.com or 3DCADbrowser.com, and just adjusted the scale and wheels to fit the track. Here’s one of my favorites (with the wheels not adjusted).”

Keppler’s advise to those interested in getting into the 3D printing industry? “Just go for it. The industryis growing fast and is not going anywhere. 3D printing offers freedom for design, and the potential for success is unlimited.”

Recommended Articles

No related posts.