How to Get Your Perfect Titanium 3D Print

Are you thinking about 3D printing in titanium? Then this blog post is for you. We wanted to make sure that you have all the information you need to produce high-quality titanium 3D prints. So let’s get started and learn the basics of DMLS 3D printing in titanium.

The Material: 3D Printed Titanium

Models made in titanium are printed from a titanium powder that is sintered together by a laser to produce metal parts. Models in titanium are very strong, precise and can have a feature size as small as 0.25mm. Here are some of the highlights of 3D printed titanium, in a nutshell:

- Our 3D printed titanium is jewelry-safe, so we expect no problems with allergies.

- Our 3D printed titanium is the strongest material you can currently 3D print with i.materialise.

- Our 3D printed titanium is a high-value material that is being used for high-end jewelry and watches.

- Our 3D printed titanium can print objects up to a size of 220 x 220 x 250 mm.

Aurora Minos by monomer

One Material, Two Finishes for 3D Printed Titanium

3D printed titanium objects with a matte finish (such as the ‘Titanium Rock’ and the ‘Ginko Leaf Cufflinks’ below) do not look like traditional shiny milled titanium parts. Instead, they are a bit grayer and more matte with a slightly rougher and less defined surface.

A Titanium Rock by DAMN

Cufflinks with Gingko Leaf by Steve Koll

The satin finish for 3D printed titanium is the way to go if you would like a shinier finish for your metal 3D prints. After a blasting process, the 3D prints will be slightly reflective.

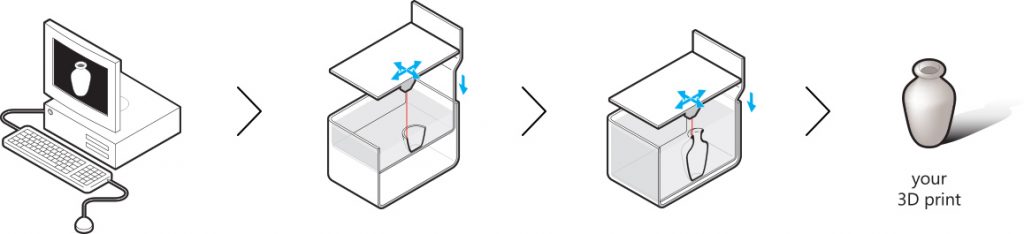

The Technology: DMLS 3D Printing

The technique used to build your design with titanium is direct metal laser sintering (DMLS). It’s similar to laser sintering technology, but instead of polyamide, a fine metal powder is used to build your model layer by layer. The powder is sintered and solidified by a laser beam that moves over a box filled with powder in minute layers. After each layer a new layer of powder is applied. Your intact model is then lifted from the powder bed. If your model needs support structures to keep the model structurally sound or to support it while the 3D printer builds it, the titanium support structures will have to be removed manually.

With DMLS it is possible to make non-rectangular, organically shaped objects that are impossible to produce through any other process.

The Design: How to Get a Great Titanium Model

Titanium is our strongest 3D printing material. And that’s what you will notice when you design a 3D model for this material. In order to receive the titanium 3D print you were looking for, you should try to keep these simple tips in mind:

- Wall Thickness: The minimum thickness of a ‘wall’ of your 3D model can be as low as 0.4mm! For most of our materials this value typically is in between 1 and 3mm. To be on the safe side, we’d suggest you nevertheless to stick to a minimum wall thickness of at least 1mm for titanium prints (especially if you plan to make something small such as the band of a ring).

- Detail Size: Thanks to our DMLS printers, you can go into a very fine level of detail. The distance between the wall of your model and the detail surface can be as little as 0.25mm!

- Dimensional Accuracy: Due to heating and cooling processes in the titanium, a 3D print can be slightly bigger or smaller than your original design intended. However, DMLS is by far the metal 3D printing process with the highest dimensional accuracy. With titanium, dimensional accuracy is generally better than 2% for outer dimensions.

- Geometry: Angular shapes, right angles and straight lines will tend to look less attractive than organic or freeform shapes. Angles of less than 35° tend to lead to poorer surface quality. Steep angles of more than 35° tend to lead to better, smoother and nicer surfaces. An overhanging structure (e.g. underside of a table) will tend to have poor surface quality. The most ideal shape to make when using DMLS is that of a mesh. These shapes make it easy to design for this process and deliver the best results.

Learn more about 3D printing in titanium on our dedicated material page. If you created a 3D file that is ready to be printed in titanium or our 19 other 3D printing materials, make sure to upload it via our online 3D printing service.

If you need more information about 3D modeling, make sure to take a look at our tutorial on how to cut costs for your next 3D printing project and which 5 modeling mistakes you need to avoid.

Recommended Articles

No related posts.