Laser Sintering

melting powder with laser

Laser Sintering

melting powder with laser

Multi Jet Fusion

fusing powder with agent and heat

Multi Jet Fusion

fusing powder with agent and heat

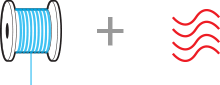

Fused Deposition Modeling

melting filament

Fused Deposition Modeling

melting filament

PolyJet Printing

curing liquid resin with laser

PolyJet Printing

curing liquid resin with laser

Lost Wax Printing & Casting

curing wax, making mold, casting

Lost Wax Printing & Casting

curing wax, making mold, casting

Indirect Metal Printing

gluing powder, green state model & firing

Indirect Metal Printing

gluing powder, green state model & firing

Metal 3D Printing

melting powder with laser

Metal 3D Printing

melting powder with laser