Modernizing Traditional Material with 3D Printing: Jade Crompton’s “Digital” Ceramics

Ceramics has been a common material in our daily lives since the prehistoric age. Its image not having changed much from the 18th century pottery workshop, many of us still see ceramics tableware as an artisanal product. Jade Crompton, a Masters student at Liverpool Hope University specializing in Ceramics and Digital Design, is on a quest to change our perception of this traditional material. Her one-of-a-kind ceramic tableware is the fruit of her unique production methods that incorporates digital design, 3D printing, molding and casting. How is her experimental design approach modernizing ceramics with the help of 3D printing? Read on to find out.

Jade Crompton, a Masters student at Liverpool Hope University

Jade Crompton gets her inspiration from the elements in nature such as rocks, ice and lava. Just like her latest Crystal Tableware Collection, her nature-inspired design always gives a beautiful twist to a set of tableware for everyday use. Moreover, the mineral-like geometric shapes come with smart functionality. This charming coffee cup, for example, is not only perfect to enjoy an afternoon macchiato but is also designed to give a comfortable grip and a better insulation thanks to its double-layered surface.

Macchiato Cup from Crystal Tableware Collection by Jade Crompton ©Jade Crompton

Jade’s project combines ceramic material, digital design and 3D printing, but without directly 3D printing in ceramics. So how is 3D printing playing a role in her project if it’s not directly 3D printed? Let’s take a closer look behind the scenes of Jade’s Crystal Tableware Collection.

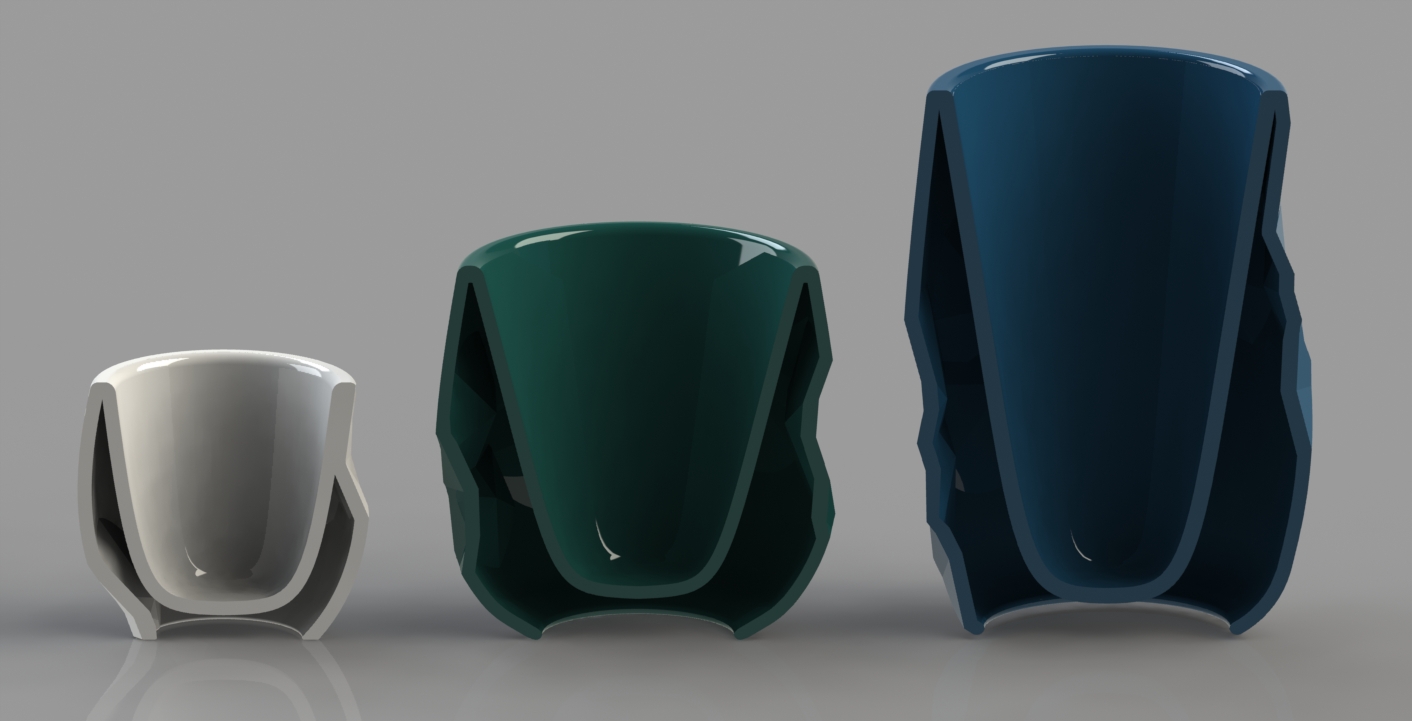

Crystal Collection renders on Solidworks ©Jade Crompton

Just like other designers using 3D printing to create their final products, Jade’s creation starts with a 3D model. She develops her 3D design and rendering on SolidWorks, then chooses the ideal design to 3D print. For the Crystal Tableware Collection, she sent these 3D models to i.materialise to have them 3D printed in polyamide.

3D printed master coffee cup molds in Polyamide ©Jade Crompton

Once the 3D printed polyamide models are ready, Jade moves on to the next step: molding. First, she applies light sanding and lacquer coating to the print so that she can achieve the best surface quality for the mold. Coating the 3D printed model’s surface protects the 3D print from water absorption, allowing her to remove the model from the mold easily in later steps.

Making my moulds of #3dprinted models with my cat looming over me! He’s so nosey! Haha takes my tools for toys #cats pic.twitter.com/xyZpqNOWIq

— Jade Crompton (@_jadecrompton) August 6, 2015

A more conventional way to make a master model for ceramic molding is to use plaster or clay, but Jade says that 3D printing greatly speeds up her mold-making. “The benefit of 3D printing the model is that I can create multiple copies of the mold without the model wearing away or distorting as plaster or clay models tend to. This helps speed up my production time casting,” she told in an interview with TCT magazine.

When the mold is all prepared for slip casting, she pours semi-porcelain into it. “Casting my molds has to be my favorite moment of any project: this is where my designs come to life for the first time. Using a 3D printed model for my mold meant that I had a clean piece to mold from: this also meant that when I cast from the molds there was minimal effort needed to clean them up,” Jade noted on her blog.

This is where the designs come to life for the first time. ©Jade Crompton

Jade’s collection after casing and underglazing. ©Jade Crompton

After several attempts to optimize the glazing and firing result, ceramics in rich colors inspired by crystals came out of the oven. In her final photoshoot at a Starbucks in Liverpool, you can see the warmth of her ceramic pieces perfectly blending in with the friendly atmosphere of the café.

©Jade Crompton

©Jade Crompton

“My final thoughts for my collection are that 3D printing and ceramics has been a unique but complementary pairing for me; I have been able to combine two exciting design areas, both of which I am greatly invested in, and I can use them to create something very new. I know I could continue designing my collections in SolidWorks and 3D printing the models and still create something new every time. The process of using digital software to design, analyze, prototype, model, print and mold successfully has helped me to speed up production time, maintain accuracy, allowed me to produce multiple molds from single models and also to prototype and test out designs before producing final pieces, saving me time and money.”– Jade Crompton

If you fell in love with Jade’s charming ceramic tableware just like I did, you can order your very own cups, bowls and plates on her website. Can’t wait to see her next collection? Be sure to follow her on Twitter for regular updates. If you’ve already designed something for your 3D printing project, simply upload it on i.materialise.com and choose your favorite material from more than 100 options!

Recommended Articles

No related posts.