.MGX opens world”s first store for 3D printed goods

.MGX, Materialise’s high end design label for 3D printed furniture and lamps, just opened the world’s first physical store for 3D printed goods. The .MGX Flagship store is in Brussels” exclusive Sablon district. At the store people can look at and explore .MGX’s lighting and other collections. In the future .MGX will showcase new designs and exhbitions by its designers in the store. You could obtain .MGX items in other design stores world wide previously such as New York”s wonderful Moss but this is the first dedicated .MGX store. It is also the world’s first store dedicated to 3D printed items, we’re guessing it won’t be the last!

The .MGX Flagship Store is located at Rue Joseph Stevensstraat 31 – 1000 Brussels (Zavel/Sablon).

UPDATE: We take you inside the .MGX store here.

The Rhino & i.materialise 3D printing Design Challenge

Together with McNeel we would like to stimulate Rhino artists & designers worldwide to get the most out 3D printing. We both want to encourage stimulating, innovative and creative 3D printed products that are “Future Forms Today.”. That’s why we’re jointly announcing the Rhino & i.materialise 3D Printing Design Challenge and making over $1000 in prizes available to you.

What can you win?

- First place wins $500 in 3D printing & an i.materialise Appear lamp.

- Second place wins $300 in 3D printing.

- Third place wins $200 in 3D printing.

How will we judge the contest?

McNeel Europe & i.materialise team will jointly judge the contest. We will be looking at people who show the power of Rhino & 3D printing in their designs. We will be looking at designers and artists that can make “Future Forms Today.” We will consider the originality and presentation of the design. We will also take into account if you use maximize the power of 3D printing in your product. So is your pro

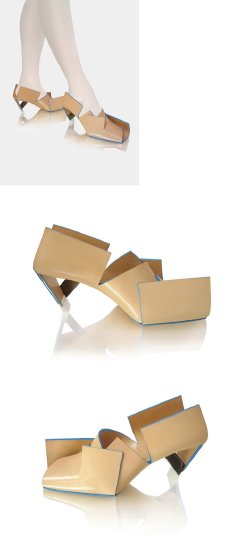

i.materialise interviews groundbreaking shoe designer Marloes ten Bhömer

In my mind there are only two shoe designers that are really revolutionizing shoe design. One is Rem D Koolhaas of United Nude and the other Marloes ten Bhömer. Both a are using cutting edge materials and design to make shoes contemporary and amazing again.

Marloes ten Bhömer is a lauded designer who has been called “one of the most promising designers of her generation”. She uses innovative production techniques, new materials and completely different ways of looking at form & function to redefine footwear. Marloes’ Rapidprototypeshoe, pictured below, is a great example of using 3D printing to create wearable footwear. We interviewed Marloes to find out more about her beautiful shoes.

Joris Peels: Why use 3D printing?

Marloes ten Bhömer: 3D printing is interesting to me on various levels.

It’s quite difficult to convince manufacturers to produce parts for products that are outside their usual industry. In my case I use production methods and materials that are rarely o

The Google SketchUp lamp Challenge winners 3D printed

We wanted to share the winning designs of the Lamp Challenge we conducted together with Google SketchUp. We think that the four lamps we chose look incredible 3D printed. What do you think? Which one is your favorite?

If you”re a designer you can go here to learn how to 3D print your own lamp. Not a designer? No problem. You can individualise your own Appear lamp here.

Congratulations to the winners and thank you for everyone that participated. We enjoyed all 55 of your designs and are really very happy with the results of the competition.

Special Jury Award for the Amazelight by Oscar Rottink.

Third place for HD Studio Lamp by Zach Hines & Oliver Dibrova.

In second place: Parasite by Paradox.

In first place, the 3D Maze by Corre.

i.materialise, mi logo es su logo

We are in the process of rebranding i.materialise. In the months to come you will see many changes in the way we present ourselves to you. As a part of this we are today unveiling our new logo.We thought long and hard (together with brand identity agency, thepubagency) about how we would explain ourselves to the world. We really wanted a logo that would encapsulate the fact that we are your 3D printing service and manufacturing partner. We know that we are the sum total and expression of your creativity and we wanted to make this clear at all times.

For this logo we will do something unique & original together with you. We will, unlike other companies, not have one symbol as a logo. Our logo will not be the same. Our logo will change. We will even use many different versions of our logo at any given time. The new i.materialise logo is simply the word “i.materialise” written by you. You can simply take a few minutes to hand write and then upload a logo to us here. We will col

Vormgevers РStefan Sch̦ning

Belgian designer Stefan Schöning is probably best known for his redisgn of the corporate identity for the Belgian Railways and the resulting iF product design award & the red dot product design award. He also does a lot of product design for his Stefan Schöning Studio & design label polyline. Recently Stefan was featured on the Belgian TV show Vormgevers. The Belgian channel Canvas let us put the resulting clip on YouTube. The TV show is in Dutch and has no sub titles. But, if you do happen to speak Dutch the segment shows you how Stefan uses 3D printing to make prototypes for his cutlery collection. You can see him interact with his client and it is a great look inside the entire process from start to finish. It is also a good detailed example of how designers use 3D printing in their design process to itterate and communicate with clients. They discuss the forms, the design and lots of disparate elements of the process.  If you don”t speak Dutch at 4.14 there is some

3D Printing the Individualized Appear Lamp

Introducing the individualized Appear Lamp.

The Appear Lamp holds a secret. Your secret. Once you turn it on, it reveals itself.

You can individualize your own appear lamp with your very own hidden message. You can play with the different fonts and see how your lamp will look online here.

The lamp costs $99 ($19 including shipping to the States) and comes complete with light, fitting and stand. The lamp comes in both a European and US version. The Appear Lamp is 3D printed in polyamide and manufactured with care in Belgium.

What will you reveal? Will it be a message for a loved one? A joke? A surprise? Explore your creativity with the Appear.

We would like to thank the team at .MGX for all their help with the engineering of the Appear and for letting us build on their ten years of expertise in 3D printed lighting. You can find more images of the Appear Lamp on Flickr.

Genetic Robots made with 3D printing without a human designer

The German high tech research Fraunhofer-Institut has just unveiled its Genetic Robots. The robots are made by using genetic algorithms that come up with the optimal robot shape and form without the involvement of any human designer. The optimal form is decided based on a physics engine that takes into account the tasks and terrain and then designs the robot accordingly. The robots are made of ball and socket joints and connecting tubes and can change shape depending on the required tasks. The resulting robot is then 3D printed.

This is nothing short of the future of design. By looking at the fitness of a design before the robot is made and by individually designing and 3D printing only the best suited designs, more optimal designs can be produced. No longer do designs have to be “for all terrains” or for all uses but they can suffice for a single task. In effect you have disposable highly specialized robots. With Moore’s law and other technology accelerators in effect this comm

Fiction vs. Reality: What 3D Printing Is and How Pop Culture Sees It

How Pop Culture Sees New Technologies

I love CSI and its legion of lab coat wearing copies. One of the reasons I like those shows is that science is one of the heroes of these series. I enjoy hearing about new technologies such as tricorder-like scanners, new ways to lift fingerprints and minute trace evidence that can be tracked back to its source.

My only worry is that every time one of these shows deals with a subject that I understand they screw it up. Probably the most famous example is the CSI New York episode where one cast member says she will “create a GUI interface using Visual Basic to see if I can track an IP address.” Believe it, there is a clip right here.

It’s as if someone got the 1997 edition of ‘The Information Superhighway for Dummies’ and randomly strung glossary entries together to form a sentence. This error could have been averted by one phone call placed to most of the people I know.

A 3D Printer in the TV Show ‘Bones’

Recently I watched a Bones epi

Customize Your Ikea furniture with Mykea

Mykea is a Dutch company that lets you personalize your Ikea furniture. According to the company, “We are now the company that enables everybody to customize their Ikea furniture and thereby giving their interior a trendy look and making their homes more personal and unique with the MyKea Design Covers.” The covers, giant stickers, can be made for a number of furniture pieces. You could take your own design or buy one from a designer. Once you order a piece it is delivered to you and you can stick the cover on your furniture.

Designers can participate and earn money by uploading designs and selling them on the site. The company aims to create a community and the website is very slick and easy to use. I wonder if they”ll stick to the covers or offer more services such as painting or even more fundamental customization. Previously several groups of artists and designers were involved in more radical customization with Ikea furniture with Hacking Ikea projects. Do check ou