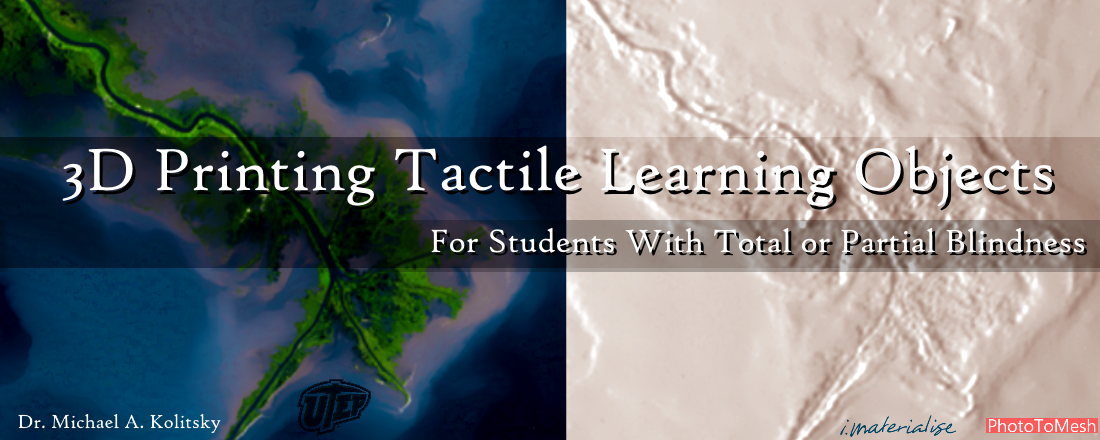

3D Printing and Public Education Join Forces to Create Tactile Learning Objects for Students With Total or Partial Blindness

Could 3D printing launch a revolution for 285 million people with total or partial blindness? Many of us learn by visually browsing thousands of texts, images, and videos. Until recently, hundreds of millions of people with total or partial blindness could not access most of this information. They relied on slow-moving braille translations, a situation that noticeably improved with the launch of the internet and its accessibility tools (i.e. text-to-speech software.) The internet created a revolution, and another one is already underway: 3D printed “tactile learning” objects.

3D printing can quickly turn 2D images into textured 3D images that people can touch and learn from. We spoke with University of Texas at El Paso biologist Dr. Michael A. Kolitsky to discuss how 3D printing is changing education, and how it will make new educational opportunities accessible to students with special needs.

Dr. Michael A. Kolitsky is a biologist, his Ph.D. is in Cell Biology from Temple University in Philadelphia, PA. He taught for over forty years and received Distinguished Teaching Award at the University of Texas at El Paso.

His interest in tactile learning products sparked to life after working together with a blind colleague.

“A colleague who has been blind for years bought a 3D printer and asked me for some 3D print files that he could use to test his machine. I sent him a file of Saturn from the Hubble collection. He emailed me a few days later and said his 3D printer worked great but he thought that the rings of Saturn were circular, not elliptical. And then in the next sentence, he said, “ah, we’re viewing Saturn from the side so the circular rings appear elliptical.”

A Bas-relief of Saturn. One side is flat, the other side has a printed, raised surface. This is an example of a tactile learning object.

The moment presented a learning experience for both men, and Kolitsky emerged fascinated by how an absence of physical sight affects the learning process:

“I was stunned. He learned about the rings of Saturn, but always envisioned the illustration of Saturn as having round rings, like the rings that go onto your finger. Yes, Saturn does have round rings but only if they are viewed from the north or south poles. From the side, the rings appear elliptical. This was my first experience with how 3D printed tactile can enrich the learning experience for the blind or visually impaired.”

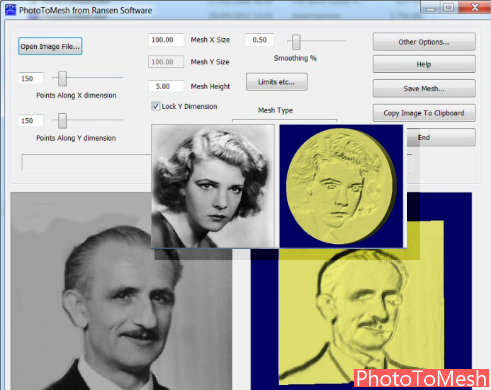

About two years ago Dr. Kolitsky has discovered 3D printing and a software program named PhotoToMesh, on which users can make a 3D bas-relief from 2D “.JPG” images.

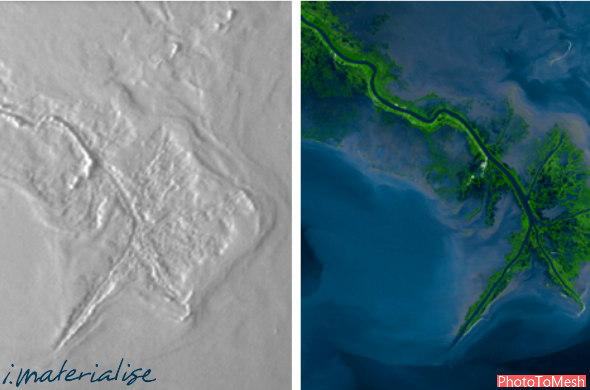

He is researching the possibility of making 3D prints of images from microscope slides, or of what is seen with a telescope or earth-facing satellite. These 3D prints could make it easier for blind or visually impaired students “see” through touch, and to partake in classes that may have previously struggled to accommodate them.

3D models generated by PhotoToMesh are rectangular or square parts. They have a flat base and a detailed “top” side containing the tactile embossed-like duplication (similar to bas relief) of the 2D image from which it was made.

Dr. Kolitsky has made hundreds of prints, both on his home 3D printer and through the high-detail printing service i.materialise.

Often times, students with full blindness have to imagine what maps look like. 3D printing a “tactile object” map makes a big difference.

“I make 3 or 4 3D prints on my home 3D printer before I get the one that is the best.A lot of times, my home 3D printer is my experimental tool to see if the tweaking and adjustments I have to make to an image in Photoshop to get the right tactile feel works in the final product and then I can send that file to i.materialise for the final production and size determination. I enjoy having this option ready, because industrial-grade high resolution printers are not in my budget.”

It is important to use braille in the tactile learning objects, and braille symbols can also be 3D printed.

Dr. Kolitsky is disheartened that he has never had a student with total or partial blindness enroll in any of his classes. He believes that blind or visually impaired students shy away from classes in disciplines that are heavily dependent upon visually “seeing” images. Compelled by a sense of duty, he feels that providing image-intensive courses with 3D-printed “tactile learning objects” will encourage more participation from students who are blind or visually impaired. Given the push for “universal design” that draws its inspiration from advances made during the 1990s Internet Age, we should begin to see a future in which 3D printing plays a greater role in creating a great variety of tactile learning objects.

“My focus at this time is to demonstrate how 3D prints can be used for making tactile learning objects. The majority of learning objects produced today are entirely digital, and not fit to be used by people with visual impairments.”

Dr. Kolitskyseeks to improve the existing technology, and emphasizes the importance of making these objects practical instead of ornamental. One important feature he is already implementing is pen-based a “touch to talk” feature:

“For one approach, I’m making line graphics for 3D prints so that the lines can lead to a particular spot off the print. This allows a Livescribe pen to be placed on that spot, and an audio description of what the line graphic is pointing to can be heard. In a sense, I want to make 3D printed tactile learning objects talk or speak when touched at the right spot.”

Perhaps these advancements in education technology will give students with total or partial blindness greater access to rewarding careers in internal medicine, cartography, biology, technical illustration, and nanotechnology.

Would you use 3D printed “tactile learning” objects to learn?

Recommended Articles

-

How to Paint Polyamide 3D Prints: Master Artist Shares His Knowledge Tutorials

-

Top 10 3D Model Databases: The Best Sites To Download 3D Models For 3D Printing 3D Printing News

-

How to Improve Your Creative Business with 3D Printing 3D Printing Art Fashion Jewelry

-

3D-Printed Camera Accessories: Improve Your Photography with 3D Printing 3D Printing Featured Designs Hobby & Tech