Design Specifications

- 630 x 330 x 550 mm (natural)

- 270 x 150 x 150 mm (dyed)

Pricing Info

The pricing for Alumide is based on the volume your models take up in the 3D printing machine. This includes the volume of your models and the surrounding space they require in the printer’s build chamber to ensure a successful print.

For Alumide, we charge a minimum price per ordered piece. Unlike the startup cost (which is applied to most materials), this cost vanishes when the price is higher than the minimum price. And if you order two or more copies of a model, the price automatically decreases because the preparation of multiple copies can be carried out more efficiently.

Typical Use

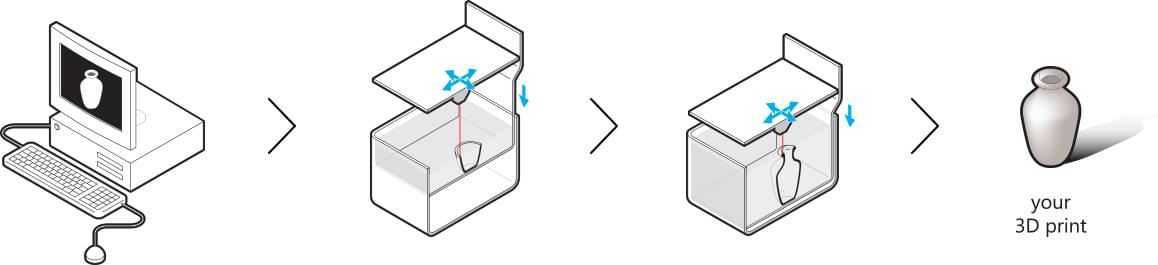

Technology

Additional Information

- With some exceptions, the mechanical characteristics are similar to polyamide. Please check the technical specifications tab for more details.

- The color of dyed alumide models may vary.

Basic Sample Kit

Includes a sample of polyamide, alumide, standard resin and steel (natural polished).

Alumide Sample Kit

Includes a matt aluminum, Asphalt Black, Brick Red, Bordeaux, Rusty Orange, Sparkly Blue, Petrol Blue and Moss Green dyed sample.